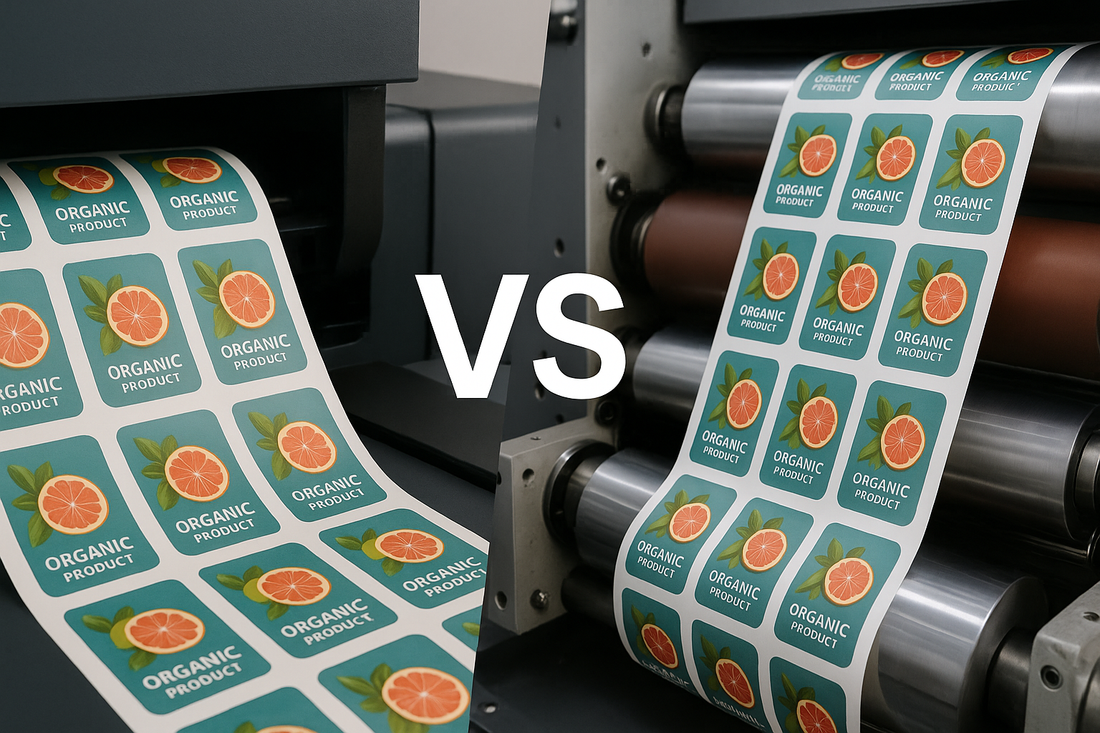

Digital vs. Flexographic Label Printing: What’s Best for Your Run?

Share

When it comes to custom labels, the print method you choose can greatly affect cost, turnaround time, artwork flexibility, and final quality. In this post, we’ll break down the two main technologies - digital printing and flexographic (flexo) printing - explain how they differ, and help you decide which is best for your job.

What Are the Two Technologies?

Digital Printing

Digital label printing sends your artwork directly from a digital file to the printing press — no printing plates required.

Key characteristics:

- Low setup cost (no custom plates needed).

- Ideal for variable data such as unique codes, SKUs, or personalized designs.

- Shorter lead time with fast setup.

- Best for small to medium runs.

- Some limitations on certain materials or finishes (though this gap is shrinking).

Flexographic (Flexo) Printing

Flexographic printing uses flexible relief plates, each corresponding to one color, mounted on rotary cylinders. As the substrate passes through, it picks up ink from these plates.

Key characteristics:

- Higher setup complexity and cost (each color requires a plate).

- Excellent for large print runs with consistent artwork.

- Works with a wide range of substrates and finishing options.

- Produces durable, long-lasting labels suitable for industrial or outdoor use.

- Cost-effective at scale — per-label cost drops as quantity increases.

How to Choose: Key Factors

1. Run Size

- Short runs → Digital printing is more economical.

- Large runs → Flexo becomes more cost-effective once setup costs are spread out.

2. Design Complexity and Variations

- Multiple SKUs or frequent design changes → Choose digital.

- Single design with high volume → Choose flexo.

3. Substrate and Finishing

- Need specialty materials (metallics, textured films, foils)? Flexo has more finishing options.

- Standard paper or film? Digital may suffice with faster turnaround.

4. Lead Time and Flexibility

- Digital = quick setup, faster lead time.

- Flexo = longer preparation but higher efficiency once running.

5. Cost Per Label

- Digital: Lower initial cost but higher per-label price on long runs.

- Flexo: Higher setup cost but lower per-label cost for bulk quantities.

6. Durability and Performance

Flexo printing often provides superior ink adhesion and resistance to heat, water, and abrasion — ideal for industrial, outdoor, or refrigerated applications.

7. Sustainability

Digital printing tends to create less waste since there are no plates and minimal setup material. Flexo can generate more waste in short runs but performs efficiently at scale.

Which Is Best for Your Run?

Here’s a quick summary to help you decide:

- If you need small runs or market testing, go with digital.

- For high-volume production, flexo offers better cost efficiency.

- When managing frequent design changes, digital provides more flexibility.

- For premium finishes or specialty materials, flexo is more versatile.

- If you need a fast turnaround, digital is ideal.

- For maximum cost savings on large orders, choose flexo.

Many businesses use a hybrid approach — digital for small or personalized batches and flexo for large-scale production.

Why It’s Important to Choose the Right Partner

Neither method is “better” in every situation — the best choice depends on your product, artwork, and budget. That’s why partnering with an experienced label printer that offers both options can save time, money, and stress.

A knowledgeable provider will guide you through:

- Comparing costs between digital and flexo for your exact run size.

- Choosing materials compatible with your application.

- Ensuring consistent color and quality across batches.

Partner With PDQ Labels

If you’re looking for professional custom labels printed in Australia, visit shop.pdqlabels.com.au.

PDQ Labels offers:

- Fast, high-quality digital label printing for short runs and personalized designs.

- Cost-effective flexographic printing for bulk orders.

- Local support, fast turnaround, and flexible options for every business size.

Whether you’re a small brand testing new packaging or an established manufacturer with large production runs, PDQ Labels can help you find the perfect balance between quality, cost, and efficiency.

Final Thoughts

- Choose digital for agility, short runs, and rapid design changes.

- Choose flexo for high volume, specialty materials, and long-term consistency.

- For the best results, consult with experts who understand both technologies.

👉 Ready to print your next label run? Visit shop.pdqlabels.com.au today to explore your options and get a quote.